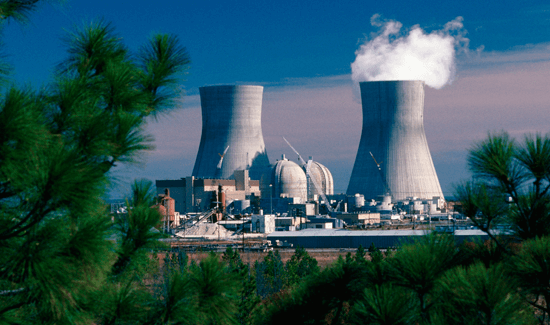

PSA is performed at the design stage of the plant using the design and updated during construction and operation of the plant. With the evolution and development of newer designs, PSA has become an integral part of the design process.

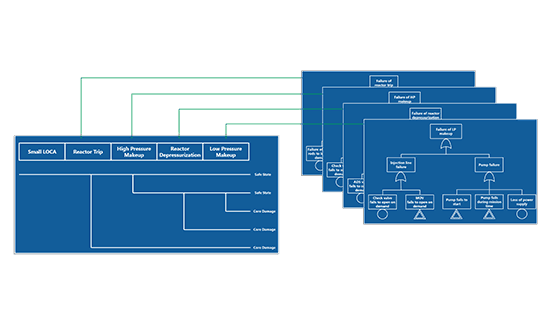

During the design process, PSAs can aid in the identification of plant vulnerabilities, inter-system dependencies and potential common cause failures (CCF). They can also be used to optimize the design of safety systems, evaluate design alternatives and make risk informed decisions.

The plant specific details are not available during the design PSA development and conservative approaches and bounding analyses are depended upon for getting an overall perspective of the risk metrics (CDF, LERF, etc.) from a NPP adopting this design.

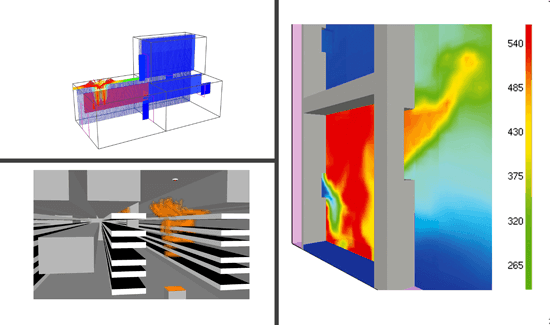

Some of the details that will be available only for operating plants include availability of emergency and other operating procedures, plant-specific operating experience, availability of operators for the assessment of recovery actions, possibility of plant walkdowns, ability to address spatial and environmental hazards, availability of plant specific system operational alignments and configurations in various plant operating states, availability of plant specific details like cable routing, door and equipment locations, fire detection and suppression system locations, pipe routing and flood barriers etc. The lack of availability of such details during design stage has a potential to reduce the realism in the PSA and therefore considering all these aspects, regulatory authorities have developed and prescribed specific requirements for design PSAs and for certification of the new designs.

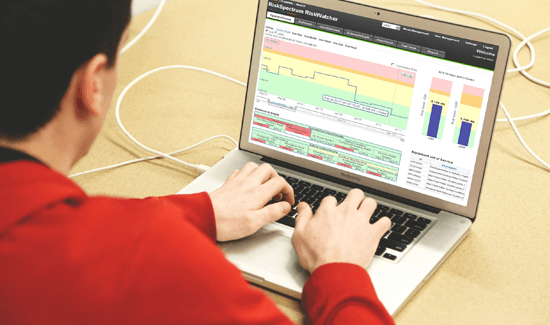

RELSAFE team has the capability and extensive experience in design PSA reviews against specific regulations, doing a gap analysis and recommending necessary improvements.