Internal Fire PSA

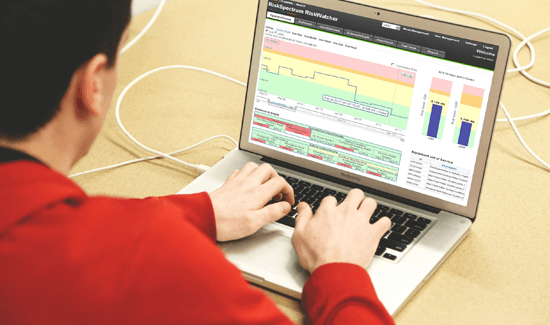

The main objective of Internal Fire PSA study is to support the evaluation of plant fire protection adequacy, plant response and readiness to mitigate fire events, and identify any vulnerabilities/weaknesses and necessary design upgrades for further improvement.

Internal fires cause disturbances in the facility which can lead to a plant shutdown whilst simultaneously affecting multiple mitigating systems, structures and components within the facility. From early full-scope PSAs to the latest Fire PSA studies based on NUREG/CR-6850, fire has been shown to be a significant risk contributor for several NPPs.

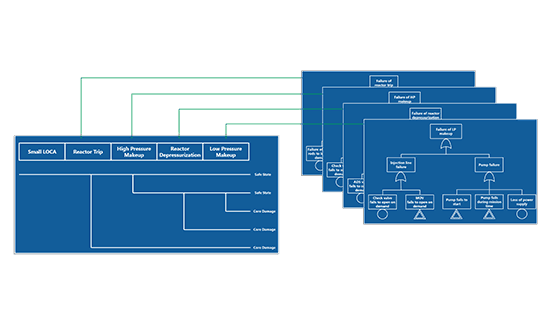

Fire PSA involves systematic identification and characterization of potentially significant fire-induced accident scenarios and their consequences in terms of failures of plant safety system components and operator actions. Multiple spurious operations analysis, electrical circuit failure analysis, detailed fire simulations for fire propagation analysis, fire event tree analysis, etc. are some special areas treated with advanced state-of-the art methods within Fire PSA. Developing a robust fire analysis database (equipment list, cable routing, fire protection details, fire barrier information and its rating, ventilation connections, etc.) and conducting fire-specific plant walkdowns/walkthroughs are equally important to achieve high-fidelity results from a Fire PSA study.

Fire PSA is important to demonstrate the adequacy of fire protection systems in preventing, confining and mitigating potential fires; to demonstrate the capability of emergency systems to mitigate fire-induced initiating events; to identify the spatial dependencies significant to risk from an internal fire standpoint; and to identify the important operator actions needed to mitigate the fire spread. Fire PSA is being mandated by regulators worldwide for effective risk-informed decision making.

Fire risk assessment is an extensive study which requires a careful choice of team with expertise in four key areas: fire analysis (fire protection engineering, fire behaviour, fire modelling, fire protection regulatory compliances), plant systems analysis and PSA, human reliability analysis (including knowledge of fire safe-shutdown procedures, fire emergency procedures, etc.,) and electrical analysis (circuit failure analysis, evaluation of multiple spurious operations, hot shorts and cable failure modes & effects analysis).

Our Consultants have extensive experience in all these areas and capability to perform full scope Fire PSA study using state-of-the-art guidelines like NUREG/CR-6850, NUREG/CR-7114, NEI 00-01, etc. and comply with specific regulatory requirements.

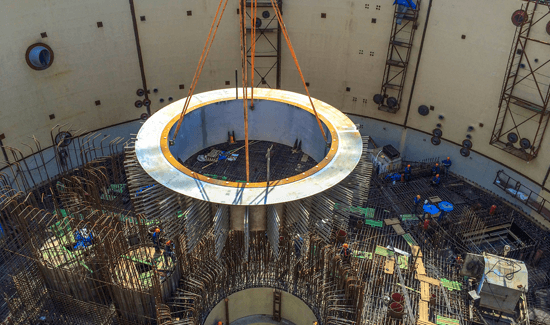

Internal Flooding PSA

Internal Flood events can be a significant contributor to the risk profile at nuclear plants. It is important to therefore analyze Internal Flood events in a consistent manner that conforms to state-of-the-art standards. There have been substantial improvements to the methods and databases available to support IFPSA in the recent times.

Internal Flood and/or High Energy Line Break (HELB) events may simultaneously impact multiple structures, redundant systems, and components at a plant. Mitigation of the event may therefore require a combination of plant system responses and manual interventions not considered in accident sequence models for other causes of an initiating event.

IFPSA is performed to identify potential flood and high energy sources and mechanisms and perform an assessment that identifies all the risk significant flood scenarios and propagation pathways across the entirety of the plant.

Several aspects of internal flood analysis are highly plant specific for example, the design, quantity, type, and routing of piping systems. These plant specific features invoke a need for plant specific IFPSA to estimate the internal flooding risk specific to a plant.

In view of the notable risk contribution internal flooding events have made in some NPPs, the importance of carrying out a plant specific Flooding Probabilistic Safety Assessment is recognized by several plant owners / utilities. IFPSA is now also mandated by several regulatory bodies worldwide.

Our consultants have extensive experience and capability to perform a full scope internal flooding PSA study applying the state-of-the-art guideline EPRI 1019194 (Guidelines for Performance of Internal Flooding Probabilistic Risk Assessment).

Turbine Missiles PSA

Failures that could occur in the large steam turbines of the main turbine-generator sets have the potential to produce large high-energy missiles that would have sufficient kinetic energy to damage even substantially reinforced concrete slabs and panels.

Large turbine missiles therefore have the potential to damage important to safety SSCs of the plant. Such missiles can render multiple systems unavailable due to its high velocity and randomness associated with the path they take. Missiles from a turbine failure can be divided into the following two groups:

(a) “high-trajectory” missiles, which are ejected upward through the turbine casing and may cause damage if the falling missile strikes an important to safety SSC, and (b) “low-trajectory” or “direct” missiles, which are ejected from the turbine casing directly toward an important to safety SSC.

It is a regulatory requirement that NPPs must show that the risk from turbine missiles is acceptably small, either because design features are provided to prevent damage or because the probability of a strike by a turbine missile is sufficiently low. This analysis is also essential for plant operators to obtain any relaxation in the frequency of expensive maintenance and testing of turbine rotors and overspeed control systems. Turbine orientation and placement, shielding, quality assurance in design and fabrication, inspection and testing programs, and overspeed protection systems are the principal means of safeguarding against turbine missiles. The risk due to turbine missiles is quantified in PSA by analysis of missile generation frequency, strike and damage probabilities.

Our consultants have the capability to perform a detailed turbine missile analysis applying the state-of-the-art guidelines and methodologies like USNRC RG 1.115 and EPRI 1009665 among others.